6201 Johns Rd. Suite 10 Tampa, FL 33634

Phone: 813-473-2470

Email: sales@cornertech.com

©CORNERTECH 2025. All Rights Reserved.

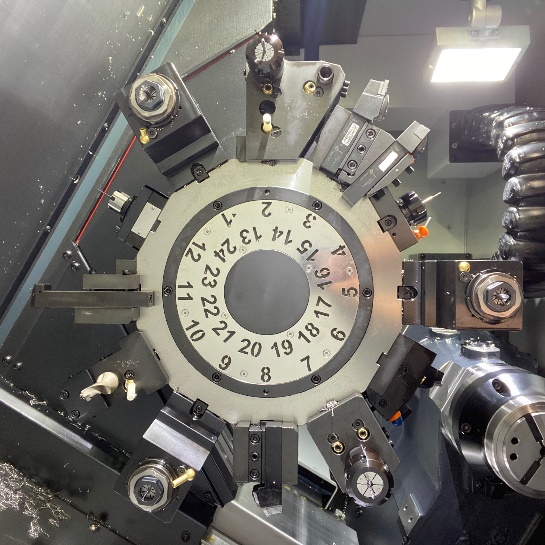

Cornertech’s commitment to leveraging advanced manufacturing technology has led us to adopt sophisticated machinery. Our work centers are designed to produce finished parts in a single cycle, ensuring remarkable precision, speed, and on-time delivery for quality parts.

Cornertech is committed to upholding the highest quality standards in our multi-axis CNC manufacturing services. We have implemented stringent quality control and inspection processes to ensure that every part produced meets the required specifications and industry standards. By using precision measuring instruments and advanced inspection techniques, Cornertech can identify and correct any deviations from the set standards, ensuring that the final product is of the highest quality and meets the expectations of our clients

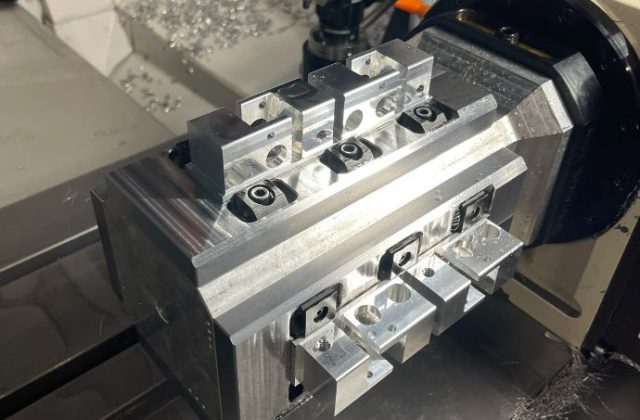

Our investment in cutting-edge CNC machinery and technology supports Cornertech’s commitment to quality and precision. Our CNC milling centers are equipped with 4 and 5-axis capabilities, allowing for high-speed production and extreme precision.

This advanced technology enables Cornertech to complete parts in fewer operations, reducing the potential for inaccuracies and improving overall efficiency. By staying at the forefront of multi-axis CNC manufacturing technology, Cornertech can deliver exceptional results for our clients in Miami.

Cornertech believes in working closely with our clients to develop custom manufacturing solutions that optimize production, reduce costs, and ensure timely delivery. Our team of machining specialists ensures that all project goals are met and is always ready to discuss new projects with potential clients.

By fostering a collaborative environment, we can better understand our clients’ needs and develop tailored solutions that meet our unique requirements.

Mike Gallagher

Procurement Manager

-

Jormac Aerospace

The Impact of Multi-Axis CNC Manufacturing in Miami

Our focus on quality, precision, and speed, combined with our collaborative approach and custom manufacturing solutions, make us an ideal choice for multi-axis CNC manufacturing services in Miami. Our advanced technology, industry experience, and commitment to customer satisfaction ensure that we can deliver exceptional results for clients across various industries.

Multi-axis CNC manufacturing is a process used in the production industry that involves the use of computers to control machine tools. Multi-axis CNC manufacturing, as offered by Cornertech, involves the creation of complex parts and components with a high degree of accuracy.

Cornertech is a leading provider of precision multi-axis CNC manufacturing services. We specialize in creating custom components for a variety of industries, including aerospace, automotive, medical, and electronics. Our capabilities range from simple 3-axis and turning work to full 5-axis simultaneous contouring, allowing for extreme precision and high-speed production.

When choosing a multi-axis CNC manufacturing service, it’s important to consider factors such as experience, equipment, quality assurance, and customer service. Cornertech has years of experience in CNC manufacturing, making us a reliable partner for producing high-quality components. Our state-of-the-art machinery and software allow us to deliver exceptional results while reducing costs and lead times.

Cornertech’s commitment to precision, versatility, efficiency, and cost-effectiveness makes us an ideal choice for multi-axis CNC manufacturing services. Our advanced CNC technology and industry experience make us a reliable partner for producing components with high accuracy and intricate designs.

Cornertech’s commitment to quality and precision sets us apart in the CNC manufacturing industry. Our advanced CNC machinery, including 4 and 5-axis capabilities, allows us to produce parts quickly while maintaining high accuracy. This level of precision is crucial for industries that require complex components, such as the aerospace and medical sectors.

In addition to our technical capabilities, Cornertech also places a strong emphasis on customer satisfaction and collaboration. We work closely with clients to develop custom manufacturing solutions that optimize production, reduce costs, and ensure timely delivery.

Our team of machining specialists ensures that all project goals are met, and they are always ready to discuss new projects with potential clients. By partnering with Cornertech, customers can expect a seamless experience from concept development to final production, making us an ideal choice for multi-axis CNC manufacturing services in Miami.

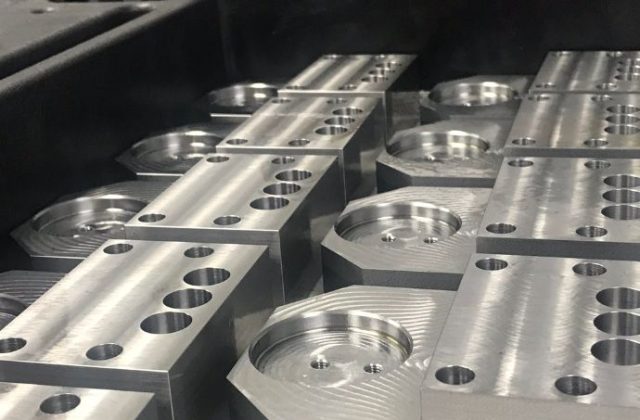

At Cornertech, we consider all production volumes first understanding the needs and goals of our clients then developing solutions that will optimize production; keeping cost down and making sure we hit delivery dates.

For larger production runs, we manufacture our own fixtures to hold multiple parts during production in order to optimize efficiency and keep the cost down for our clients.

6201 Johns Rd. Suite 10 Tampa, FL 33634

©CORNERTECH 2025. All Rights Reserved.