6201 Johns Rd. Suite 10 Tampa, FL 33634

Phone: 813-473-2470

Email: [email protected]

©CORNERTECH 2024. All Rights Reserved.

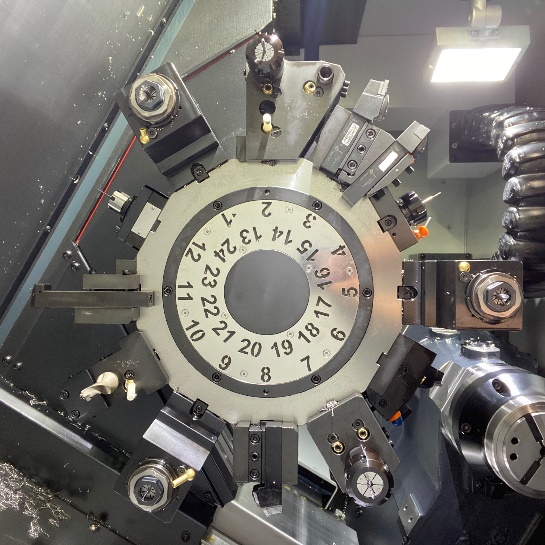

Our milling centers are all high speed and have 4 or 5-axis capability. This enables us to complete parts in two fully automated operations where other machine shops may have to use as many as six, potentially inaccurate, manually placed operations.

We can easily mill features at any combination of compound angle relative to any face on a part using 3+2 axis milling. Our CAD/CAM applications and milling centers are also capable of full motion 5-axis milling to achieve any surface contouring requirement.

Mike Gallagher

Procurement Manager

-

Jormac Aerospace

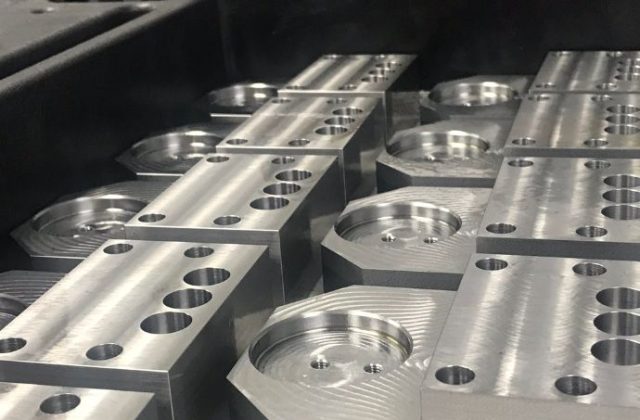

At Cornertech, we consider all production volumes first understanding the needs and goals of our clients then developing solutions that will optimize production; keeping cost down and making sure we hit delivery dates.

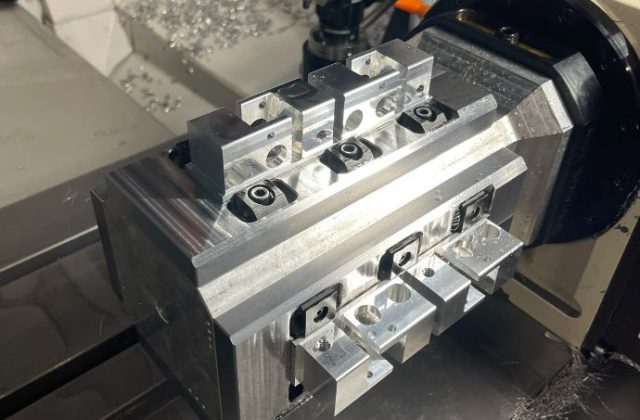

For larger production runs, we manufacture our own fixtures to hold multiple parts during production in order to optimize efficiency and keep the cost down for our clients.

6201 Johns Rd. Suite 10 Tampa, FL 33634

©CORNERTECH 2024. All Rights Reserved.