6201 Johns Rd. Suite 10 Tampa, FL 33634

Phone: 813-473-2470

Email: [email protected]

©CORNERTECH 2025. All Rights Reserved.

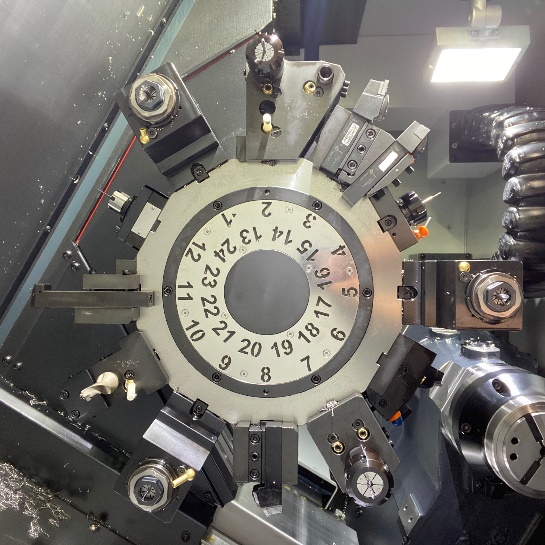

Start your Georgia high-quality metal milling services at Cornertech. We take pride in focusing on harnessing the latest advancements in manufacturing technology. Our facility is equipped with machinery designed to optimize the production process, delivering parts with unparalleled precision, speed, and reliability.

Cornertech, Inc. is committed to providing superior CNC machining services to our valued customers in Georgia and the nearby regions. Our facility houses CNC machines, allowing us to create precision-machined parts that adhere to the highest standards. We have established comprehensive quality control procedures that each machined component satisfies your precise specifications, giving you the assurance that your parts are crafted with the utmost care and attention to detail.

At Cornertech, we prioritize building strong, collaborative relationships with our clients in Georgia. Our skilled team of machinists take the time to thoroughly understand your unique requirements and develops personalized solutions to meet your needs. We provide rapid quoting and prototyping, adaptable production timelines, and competitive rates to ensure your projects are completed on schedule and within your budget. Our dedication to individualized service and support throughout your project distinguishes us as a trusted partner for premium metal milling in Georgia. By choosing Cornertech, you can have confidence in partnering with a company that is fully invested in your success and the success of your projects.

Mike Gallagher

Procurement Manager

-

Jormac Aerospace

THE SIGNIFICANCE OF HIGH-QUALITY METAL MILLING in Georgia

Whether you require a small run of parts or large-scale production, Cornertech is ready to exceed your expectations. Our ability to provide Georgia High-Quality Metal Milling, coupled with our dedication to customer satisfaction, makes us the right choice!

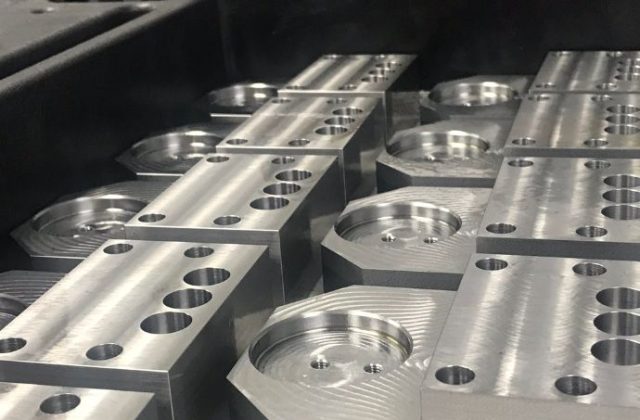

At Cornertech, we consider all production volumes first understanding the needs and goals of our clients then developing solutions that will optimize production; keeping cost down and making sure we hit delivery dates.

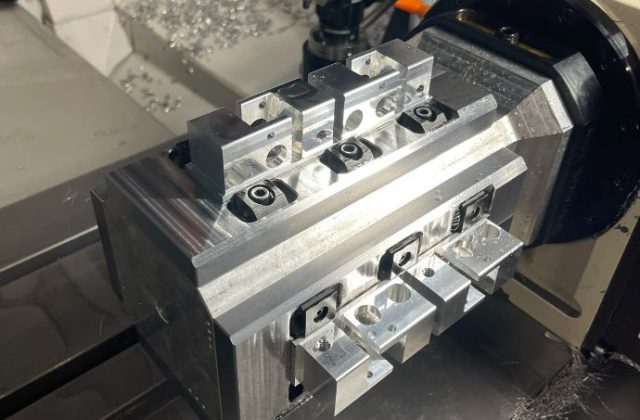

For larger production runs, we manufacture our own fixtures to hold multiple parts during production in order to optimize efficiency and keep the cost down for our clients.

6201 Johns Rd. Suite 10 Tampa, FL 33634

©CORNERTECH 2025. All Rights Reserved.