6201 Johns Rd. Suite 10 Tampa, FL 33634

Phone: 813-473-2470

Email: [email protected]

©CORNERTECH 2025. All Rights Reserved.

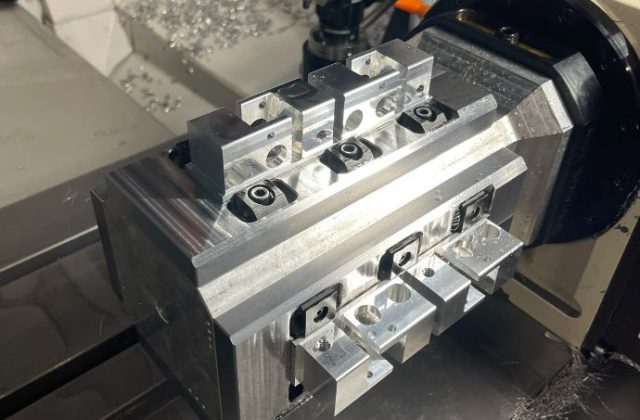

Cornertech’s CNC milling stations stand out with high-speed performance and advanced multi-axis capabilities. This state-of-the-art infrastructure allows them to finalize components in two highly automated operations, a stark contrast to other machining outfits that often rely on as many as six manual procedures.

Utilizing the prowess of 3+2 axis milling, Cornertech has the capability to mill intricate features at any desired compound angle, ensuring precise alignment with any component face. Moreover, their integration of CAD/CAM software with the milling stations also facilitates comprehensive 5-axis milling, catering to even the most intricate surface contouring needs.

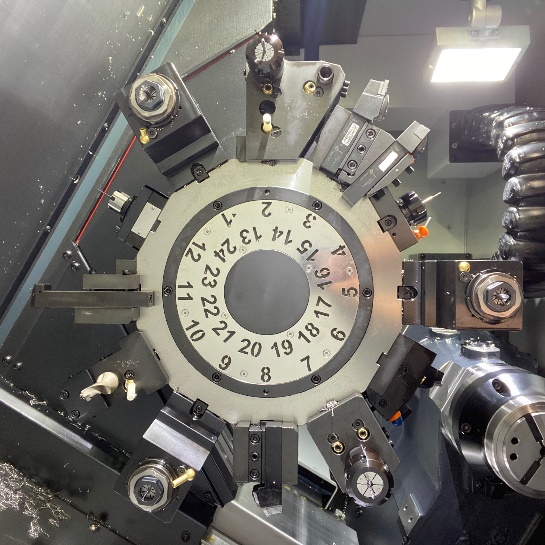

While Cornertech shines with its CNC milling services, their turning centers also boast of high-speed performance, complete with Y-axis, live tooling, and dual C-axis spindles. This integrated setup means raw material enters as bar stock and emerges as a meticulously crafted finished part, transitioning seamlessly via conveyor mechanisms.

The distinct advantage of having Y-axis and live tooling is evident in their ability to drill or mill features regardless of their positioning on the X, Y, or Z-axis – a feat not all machine shops can claim. With the incorporation of C-axis sub spindles, the precision in transferring components between spindles is unmatched, ensuring impeccable alignment and concentricity relative to the primary component features.

Mike Gallagher

Procurement Manager

-

Jormac Aerospace

CNC MILLING SERVICES IN Atlanta

Atlanta’s manufacturing landscape has constantly evolved, and at its heart lies the innovative prowess of CNC milling services. Firms like Cornertech lead the way, employing state-of-the-art CNC milling techniques to craft precision components with impeccable detail.

The adaptation of sophisticated CNC milling technology has brought about significant advantages in the manufacturing domain:

Detailed Precision: CNC milling offers the capability to craft intricate designs with utmost precision, often surpassing traditional methods.

Consistency Across Batches: With CNC milling, every product comes out with consistent quality, reducing disparities in large production batches.

Enhanced Material Utilization: Efficient and precise cutting means reduced waste of raw materials, leading to more sustainable production.

As technology advances, the emphasis is not just on the equipment but on perfecting the milling process itself:

Real-time Monitoring: Integrating real-time data analytics to oversee every step of the milling process, ensuring constant quality and identifying areas of improvement.

Automated Calibration: Advanced CNC milling machines automatically calibrate, reducing downtime and ensuring optimal output at all times.

The changing manufacturing landscape demands more from CNC milling services to remain competitive:

Adaptive Milling Strategies: Utilizing varying strategies to address different materials and design complexities, ensuring optimal outcomes.

Virtual Prototyping: Using digital simulations to preview and adjust milling operations, ensuring flawless real-world production.

Seamless Integration with Other Systems: Modern CNC milling machines easily integrate with other systems, enhancing the data flow and refining the production pipeline.

Cornertech’s achievements in CNC milling exemplify the ongoing advancements in Atlanta’s manufacturing domain. Through leveraging sophisticated CNC milling techniques and a data-driven approach, manufacturers are set to deliver top-notch components with enhanced cost-efficiency, solidifying Atlanta’s reputation as a hub of precision manufacturing.

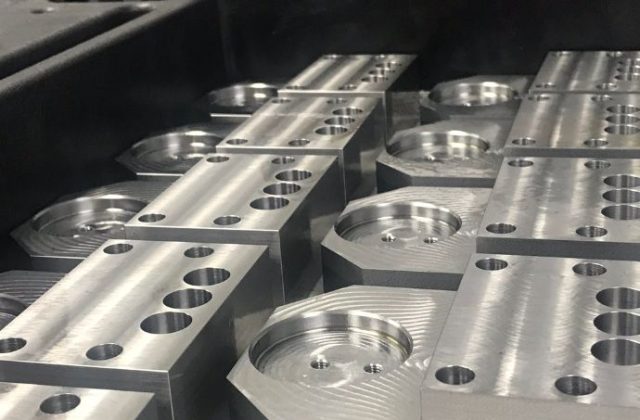

At Cornertech, we consider all production volumes first understanding the needs and goals of our clients then developing solutions that will optimize production; keeping cost down and making sure we hit delivery dates.

For larger production runs, we manufacture our own fixtures to hold multiple parts during production in order to optimize efficiency and keep the cost down for our clients.

6201 Johns Rd. Suite 10 Tampa, FL 33634

©CORNERTECH 2025. All Rights Reserved.